- TRANG CHỦ

- SẢN PHẨM

- SẢN XUẤT ĐIỆN TỬ

- GIỚI THIỆU

- GIẢI PHÁP

- BLOG

- LIÊN HỆ

- SALES

-

Thiết bị làm mạch in PCB

Thiết bị làm mạch in PCB

-

Thiết bị SMT hàn dán linh kiện

Thiết bị SMT hàn dán linh kiện

-

Thiết bị kiểm tra chất lượng

Thiết bị kiểm tra chất lượng

-

Thiết bị hàn, sửa bo mạch, chipset

Thiết bị hàn, sửa bo mạch, chipset

-

Hệ thống mẫu

Hệ thống mẫu

-

Sản phẩm theo hãng sản xuất

Sản phẩm theo hãng sản xuất

-

Giải pháp RFID

Giải pháp RFID

-

Thiết bị kiểm thử trong công nghiệp

Thiết bị kiểm thử trong công nghiệp

-

Thiết bị giáo dục, đào tạo

Thiết bị giáo dục, đào tạo

-

MAITEK Thiết kế và sản xuất

MAITEK Thiết kế và sản xuất

- Trang chủ /

- MARTIN

MARTIN

Sắp xếp:

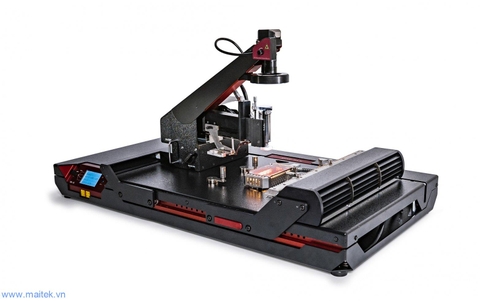

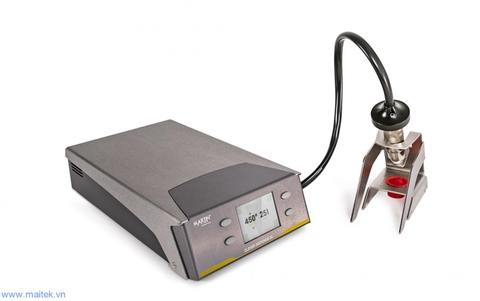

Lò gia nhiệt cỡ nhỏ MINIOVEN 05

Liên hệ

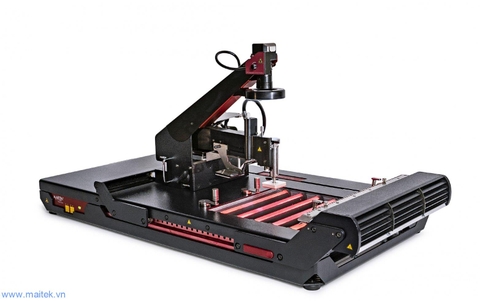

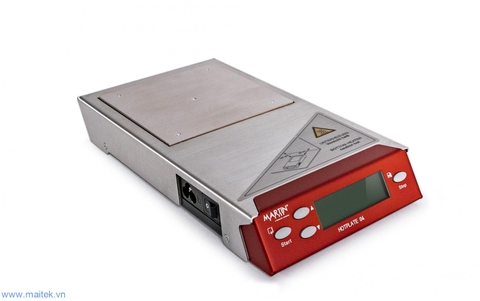

Đế gia nhiệt HOTPLATE 04

Liên hệ

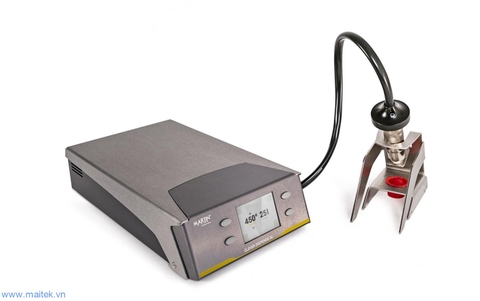

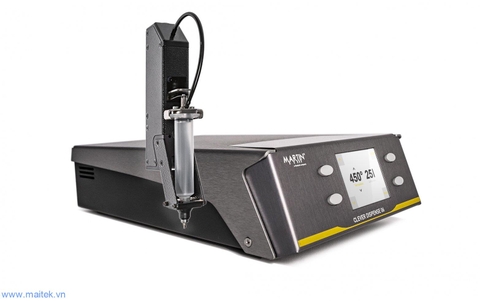

MARTIN có 30 năm kinh nghiệm trong các giải pháp Làm lại và Pha chế. Thiết bị của chúng tôi tập trung vào độ chính xác và đổi mới. "Sản xuất tại Đức". MARTIN chuyên phát triển và sản xuất các hệ thống Làm lại và Pha chế sáng tạo. Cùng với Finetech, MARTIN là nhà cung cấp hàng đầu các giải pháp công nghiệp về sửa chữa lắp ráp SMD. Khi phát triển sản phẩm của mình, chúng tôi hợp tác chặt chẽ với khách hàng từ nhiều ngành khác nhau như hàng không vũ trụ, ô tô, công nghệ y tế, điện tử tiêu dùng, công nghiệp bán dẫn, các trường đại học và viện nghiên cứu.