ABI SENTRY Counterfeit IC Detector

Chính sách bán hàng

Thông tin chi tiết

|

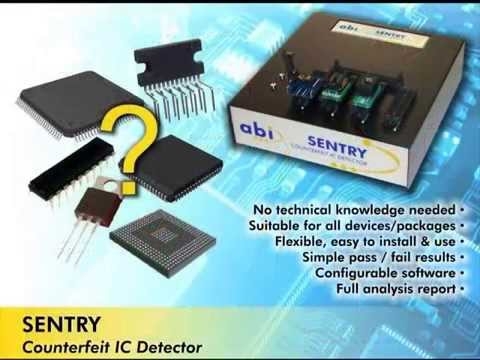

The ABI SENTRY is a unique solution for the quick and easy detection of Counterfeit ICs and components. ABI Electronics has over 34 years of experience in the field of Test & Measurement equipment as well as Contract Electronics Manufacturing. Knowledge of both industries has allowed ABI to design this product around two main concepts:

- To offer a simple and easy to use system that can be operated by any personel, and particularly non-technical staff.

- To provide a powerful solution that would lead to the detection of counterfeit devices, thus protecting a business from very high unexpected costs. |

|

Video Presentation

|

A more detailed presentation video is available here. |

Description

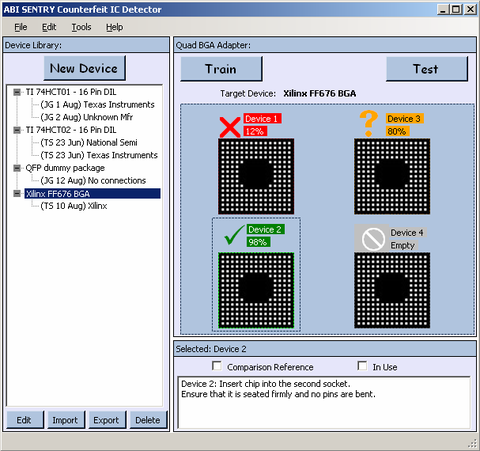

SENTRY is an easy to use tester, aimed at goods inwards inspectors and designed to measure the unique electrical signature (PinPrint) of components. The information collected is managed through a database and is used to compare known good devices against suspect components. Typically, SENTRY can easily detect missing or incorrect dies, lack of bond wires, inaccurate pin outs and pin impedance variations. Simple pass or fail results are returned after testing, offering a high level of confidence in the authenticity of components.

SENTRY does not require any knowledge of electronics to use efficiently. For in-depth analysis though, PinPrints can be reviewed and full reports can be generated. The SENTRY software also offers options for customisation and the ability to store essential documentation such as photos, PDF datasheets, web pages and images.SENTRY is able to accommodate virtually all types of components, from simple two pin devices to more complex packages such as BGA. A range of standard and universal adapters is available and custom designs can also be supplied.

In order to ensure consistency throughout the whole supply chain, SENTRY is designed to support data sharing. This means that the PinPrints of a given component can be shared between users, from the OEM through to the distributor and end user.

What are counterfeit components ?

Counterfeit [koun-ter-fit] Adj. : made in imitation so as to be passed off fraudulently or deceptively as genuine.

The manufacture of counterfeit (or fake) components is an illegal process that emerged due to the transferable value of electronics parts. Any company in the world requiring components to manufacture Printed Circuit Boards (PCBs) is at risk and many have already received batches of “bad” devices.

Counterfeiting is achieved through various processes. Devices known as “pulls” are removed from scrap boards (which have been discarded) in a process that is highly unsafe. Following superficial repairs, these devices are branded with (ir)relevant information - including a manufacturer’s logo - and passed on to an unwary buyer as genuine. Another technique is to actually produce components using the normal manufacturing capabilities in “ghost shifts” which take place outside of standard hours. However, the chips created that way include many manufacturing faults and some may not even contain a silicon die.

Unfortunately, it is not possible to differentiate counterfeit components until they are placed on a PCB and the production team runs the first tests on the complete assembly. This leads to the costly process of identifying the component(s) at fault and then removing them from all boards in production. In some cases, complete batches of finished products need to be recalled to the factory.

In the last five years, reports of counterfeit components have increased exponentially. In 2008, export of fake ICs accounted for more than 8% of global merchandise trade which is equivalent to lost sales of $6 Billion.

>>> For statistics and figures about counterfeiting, please click here <<<

Case Studies

For further information about SENTRY, and in particular its use in counterfeit detection applications, please refer to the case studies available here.

Features

- Suitable for all devices and packages

- Simple good / suspect / fail results

- No training required for operators

- Fully configurable library

- Full analysis report available

Accessories

- SOIC and PLCC Adapters

- Universal PLCC Adapter

- Universal SOIC Adapter

- Custom designs - please contact ABI to discuss special requirements.

- Calibration kit (optional)

Technical Specifications

|

Electrical Requirements

Environmental Specifications

Computer Requirements

|

Physical specifications

Specifications

Included Accessories

|