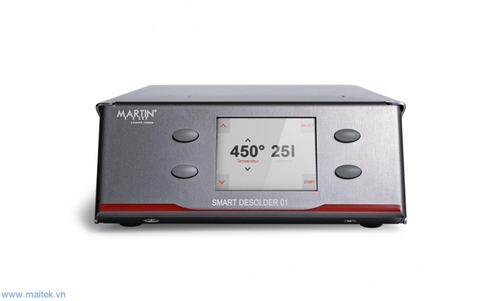

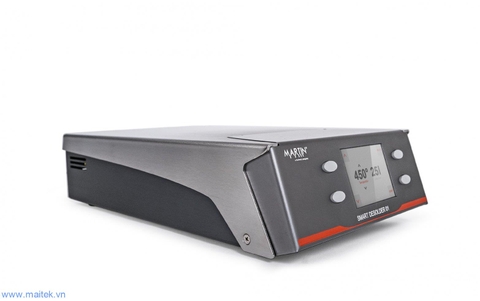

Hệ thống khò nhiệt thông minh Martin SMART DESOLDER 01

Chính sách bán hàng

Thông tin chi tiết

SMART DESOLDER 01

The SMART DESOLDER combines a manual hot gas source with a vacuum pen for extraction of residual solder. Damage to the pads from overheating or mechanical stress is avoided through targeted heating of the residual solder after lifting the component. The temperature-controlled airflow prevents the neighboring components from warming up. After melting, the residual solder is removed contactless by the vacuum pen. The soft Teflon tip prevents damage to the pads through mechanical demands. As a standalone device, it virtually fits on any work bench and can be operated very flexibly with two handheld pens. The HOTBEAM 04 / 05 under-heating system perfectly completes the SMART DESOLDER 01. Through this combination, the temperature behavior can be optimized by way of a sensor-supported or programmed preheating profile.

Product variants in the shop

| DS01.1001 | SMART DESOLDER 01 | x 1 | auf Anfrage |

|

|||

|

|

DS01.4001 | SMART DESOLDER 01 with HOTBEAM 04 - 230 V | x 1 | auf Anfrage |

|

||

|

|

DS01.4002 | SMART DESOLDER 01 with HOTBEAM 04 - 115 V | x 1 | auf Anfrage |

|

||

|

|

DS01.4003 | SMART DESOLDER 01 with HOTBEAM 05- 230 V | x 1 | auf Anfrage |

|

||

|

|

DS01.4004 | SMART DESOLDER 01 with HOTBEAM 05- 115 V | x 1 | auf Anfrage |

|

Content

- Two handheld pens with magazine for soldering and residual solder removal

- Solder nozzle 4 mm

- Solder removal nozzle complete with Teflon tip 1.4 mm

- Cleaner solder removal nozzle

- Flux filter and solder separator for old solder

Technical details

| Power consumption: | 480 W | |

| Power solder pen: | 380 W, 25 l/min | |

| Mains: | 100 – 240VAC, fuse TG,3A | |

| Pressurized air: | 7.5 l/min max. 4bar | clean, dry air |

| Dimensions: | 270 x 150 x 60 mm² |

Downloads

| Device flyer | 0.7 MB | Download |

modules & attachments

| SF03.0019 | PCB clamping holder with 3 fingers | x 1 | auf Anfrage |

|

|||

| HF00.0016 | Handy Fix 06 | x 1 | auf Anfrage |

|

|||

| HT00.0119 | Flux Creme lead-free 18g | x 1 | auf Anfrage |

|

|||

| DB50.0001 | Soldering nozzle 2 mm | x 1 | auf Anfrage |

|

|||

| DB50.0002 | Soldering nozzle 3mm | x 1 | auf Anfrage |

|