Hệ thống kiểm tra, sửa chữa, thiết kế ngược bo mạch PCB

Chính sách bán hàng

Thông tin chi tiết

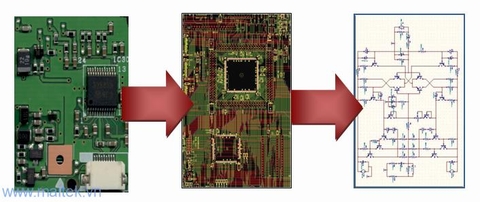

PCB Reverse Engineering, Redesign, & Repair

We are the provider of the only system in the world that can take a physical circuit board and fully reverse engineer it to provide complete manufacturing CAD data and even native format schematics. Our system includes the ability to capture precise form, fit and function for all layers of the PCB, including all inner layer geometries, drill, drill plating and layer thickness, cutouts, outline, silkscreen, and even blind or buried vias.

Data generated from PCB Reverse Engineering can be used either to manufacture replacement parts, or provide insight in repairing existing parts when schematics may not be available.

Unique Niche

Our systems are a critical component to the hardware support strategy for numerous military, governmental, aerospace, nuclear, utility, automotive and commercial firms. They rely on our system to keep their mission-critical hardware operational each and every day.

ScanCAD Systems support legacy products systems when spare parts and manufacturing data is no longer available.

Unique Technology

Internally developed software coupled with our low-cost vision platform and NIST certified calibration equipment ensures that our system is a solution that is custom tailored for your application. Our hardware and software have been specifically designed to maintain an excellent price-performance ratio, maximize your ROI and provide a unique set of tools for effective and efficient reverse engineering, regardless of the scale of your project.

Unique Process

Over our thirty years in business, we have continuously improved our process to support cutting edge technology. Whether a circuit card has two or twelve layers, blind or buried vias, and the substrate is FR4 or Thermount ™, we have the process knowledge to ensure your success.

A Case Study

A Californian power plant was forced to go offline due to the absence of a $500 printed circuit board (PCB). Their inventory was exhausted, and the original manufacturer of that PCB was no longer in business. Given the fact that the US power grid is running at capacity, the downtime was costing dearly and time was of the essence. Fortunately, the power plant was able to locate ScanCAD quickly and began to process the board immediately. The resulting CAD data was sent to a local PCB fabrication and assembly house. The resultant PCB retained identical form, fit, and function to the original and was quickly tested and put into service. Extra parts were fabricated so satisfactory spares would be on hand and the data package for the board was archived for future use. The ScanCAD system empowered this power plant and enabled them to take control of their own maintenance and decrease reliance on external suppliers.

There are two organizations in North America using ScanCAD PCB RE solutions dedicated solely to keeping Nuclear Power Plants running, not counting coal, gas, and renewable plants!

What is PCB RE (Reverse Engineering)?

You probably have a concept of what "Reverse Engineering" means, but asking "What is PCB RE?" may not be the most important question you need to ask.

Why do I need to reverse engineer a CCA/PCB?

One of the largest problems that a company can face over the lifetime of an electronic device is the maintenance of circuit board assemblies (CCAs) as replacement parts. This is much less important for consumer grade products such as electronics in toys, but far more important for complex legacy control, communication, transportation, navigation and other electronic systems.

I'm out of spare parts!

Most complex systems consist of a variety of interrelated and interconnected PCBs, which must handshake perfectly for a system to operate properly.

Components and boards can be damaged for many reasons including temperature, power fluctuation, mistreatment, aging and even insects/rodents. In many cases, failure of a single component can cause massive, complex systems to stop. Ultimately, when a component in a complex electrical system fails, you will need to merge replacement elements into the existing infrastructure. One way to do this is to design a new board based off of schematics and parts lists, but this process will not yield a board with the exact same characteristics which can lead to potential integration problems. Additionally, certain applications have extremely rigorous and time consuming qualification processes before you can install your shiny new CCA. You may even have to go through several revisions of design and prototyping before you have a working solution.

Why go through a lengthy, complicated redesign and qualification process when you can copy and reproduce an identical board with identical function?

ScanCADs PCB RE process is just that - taking an existing board, and generating design data to re-produce the exact same part that failed. The benefit of this process is that you do not have to endure a lengthy redesign and prototyping cycle since you will be matching the form, fit and function of the original part.

Reverse Engineering Systems

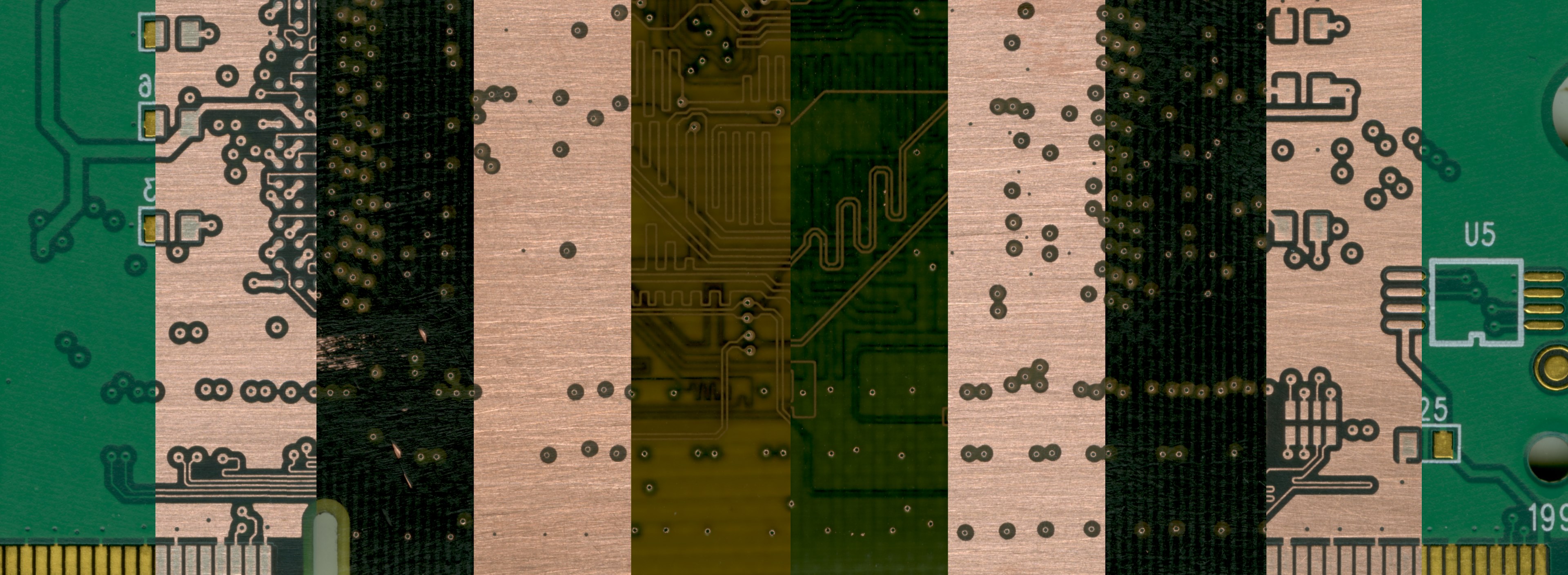

This image contains all 6 circuit layers in a SO-DIMM chip, from Bottom (Left) to Top (Right)

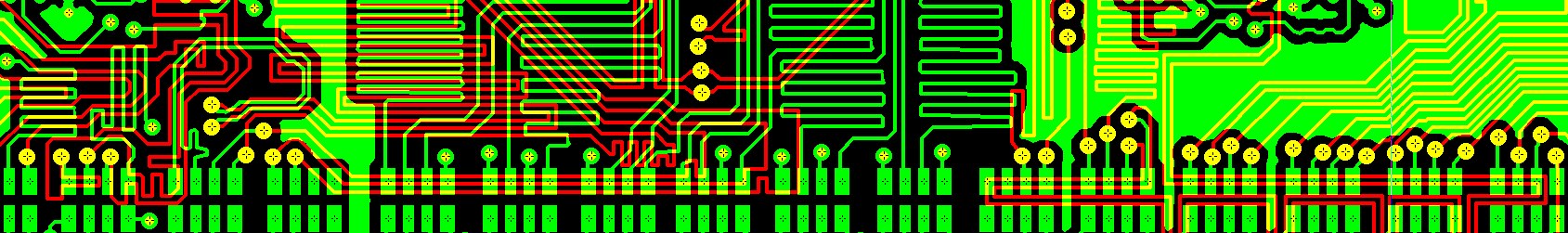

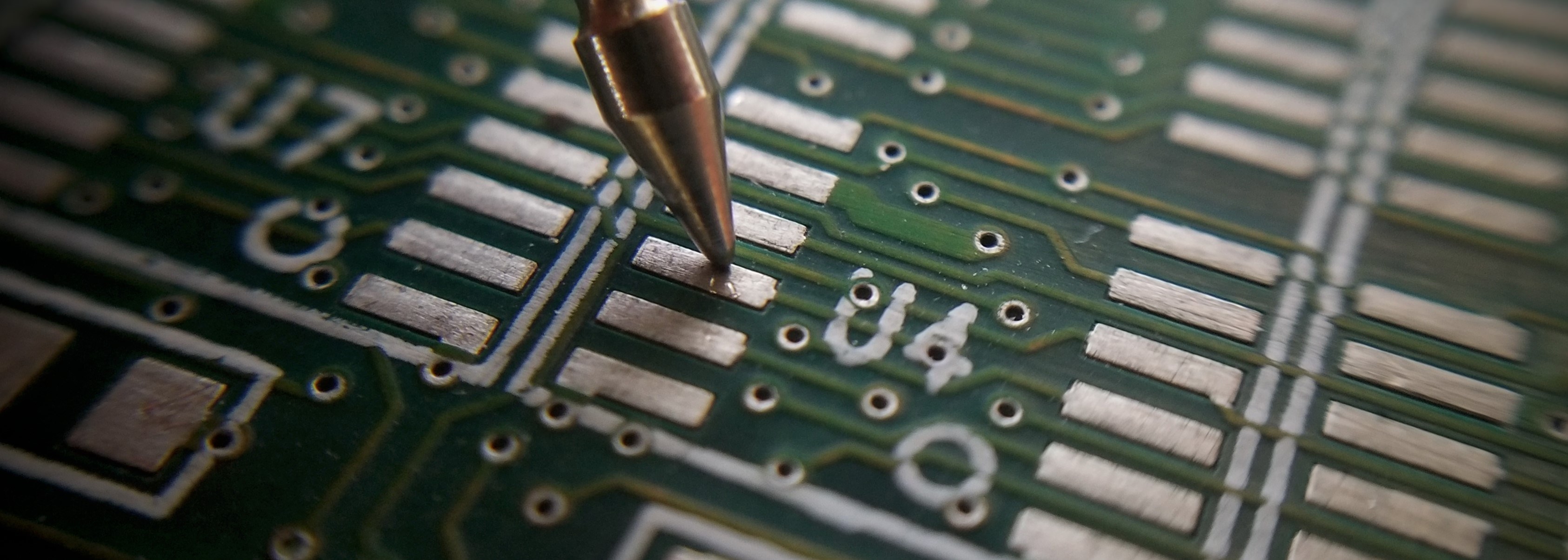

In order to generate circuit board data, ScanCADs PCB RE System utilizes proprietary milling techniques and high resolution, calibrated images as a base for generating gerber data. With a destructive RE process, each layer is imaged and aligned, and then using automated and manual processes, gerber data is generated for all layers of the circuit board. This process allows gerber data to be generated that matches the exact form, fit and function of the original board due to the fact that inner layer copper plane and circuit geometries are captured and digitized.

Top and Inner layer gerber data

The resulting data can be validated against a golden, functional board and the netlist verified to ensure proper connections between components. Once all data is captured for the board, the project is moved to the schematic generation phase, where all of the acquired data is merged into schematic.

For boards that cannot be destroyed, ScanCADs PCB RE system also supports non- destructive reverse engineering processes. While the FPT process does not yield inner layer geometries, it still produces connectivity information and can be used in conjunction with BOM information to create a schematic without physically destroying the board.

Technical Specifications*

Scanner

- High-Resolution Color Flatbed Scanner, Size A3:(400/1000/1600/2000/2400/3200/4000/ 4800 dpi) Calibrated Accuracy: ± 0.001” (± 0.0254mm)

- A3-Scanning Bed Area: 11.7″ x 16.5″ (297mm x 419mm)

- Multiple scans can be stitched together for a larger working area

Computer**

- Multi Core Processor – 3GHz

- 1TB 7200 RPM HD, 8-16 GB RAM

- CD/DVD ROM (For archive purposes)

- Flat Panel Monitor

- Ethernet Connection

- Windows 10 – 64-Bit

- 2 available USB ports – USB2 or USB3

**Recommended customer-supplied minimum PC requirements.

Additional System Components

- Precision Glass NIST Calibration Grid

- ConvertPLUS CAM Software

- Work Instruction Software (WIS)

- Custom Transmissive Lighting Package

- Custom Workstation Desk

- Scanning Accessory Package

The following are trademarks of the indicated companies: Gerber, Ucamco N.V.; Windows 10, Microsoft®; ScanCAD™, ScanFAB™, Scan-T™, ScanPLACE™ and ScanINSPECT VPI™ are trademarks of ScanCAD International, Inc. *All specifications and designs subject to change without notice.*

Datasheets

Gerber and Drill

Assembly

Netlist

Schematic