Còn hàng

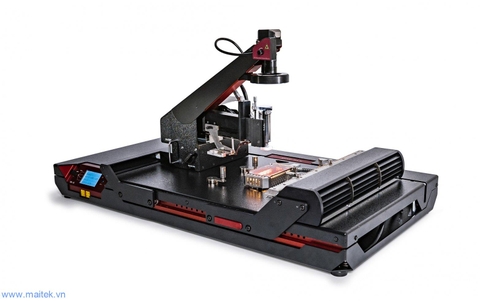

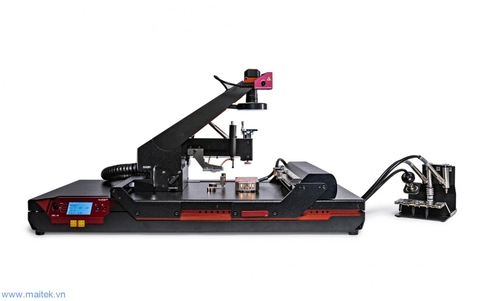

Hệ thống sửa chữa bo mạch Martin EXPERT 10.6 IV

Tình trạng:

Còn hàng

|Thương hiệu: Martin

Loại: bga

Nội dung đang cập nhật...

Liên hệ

Chính sách bán hàng

Hàng chính hãng, bảo hành toàn quốc

Cung cấp đầy đủ chứng nhận CO, CQ

Gọi lại trong 10 phút từ khi nhận liên hệ

Giao hàng toàn quốc nhanh chóng

Hỗ trợ dịch vụ 24/7

Hỗ trợ mua hàng

0906182358

Thông tin chi tiết

Expert 10.6 IV

410 W Rework station with IR under-heating system (80 x 60 mm²) and automated SMD placement process by Auto Vision Placer (AVP) incl. software EASYSOLDER 07 and DBL 06 control unit with six high-resolution sensors inputs for thermocouples (Type K). This unit is particularly suitable for small PCBs found in smartphones and PDAs with fine-pitch components in varying package dimensions.

Product variants in the shop

| DB00.1068 | EXPERT 10.6 IV | x 1 | auf Anfrage |

|

Content

- Tool set for dispensing, placing, residual solder removal and soldering with magazine

- Set of placement nozzles (BGA/CSP) 3 mm, 5 mm, 8 mm, 10 mm

- Set of soldering nozzles (CSP/QFN), 9 mm, 11 mm 13 mm, 16 mm

- Set of soldering nozzles (SO) 10x15 mm², 15x25 mm²

- Placement nozzle for manual placement of small components (0,5 mm)

- Two camera lenses (BGA und CSP)

- Two thermocouple sensors (type K)

- Two PCB magnet holder 40.5 mm (standard)

- PCB support rail 40.5 mm

- Two PCB clips to install at hand rest

- Foot switch

- Rework ABC and manual

- Intuitive software EASYSOLDER 07 with touch integration

Technical details

|

Power consumption: |

1000 VA | |

| Power solder pen: | 300 W, 35 l/min | |

| Power under-heating system: | 110 W, 2 x IR-lamps | |

| Size under-heating system: | 80 x 60 mm² | |

| Max. PCB size: | 100 x 80 mm² | |

| Resolution motion system: | 0,001 mm | |

| Placement accuracy: | ± 0,015 mm | (Flip Chip)* |

| ± 0,030 mm | (CSP) | |

| ± 0,040 mm | (BGA) | |

| High resolution CMOS-camera: | 5 Mio. Pixel, USB2 | |

| Camera field of view (FOV): | 14 x 18 mm² | (Flip Chip)* |

| 28 x 37 mm² | (CSP) | |

| 37 x 50 mm² | (BGA) | |

| Mains: | 1 Phase, 230VAC, Fuse 16A | |

| Pressurized air: | 5-8 bar, 100 l/min | clean, dry air |

| Dimensions: | 865 x 460 mm² | |

| * Optional extras | ||

Downloads

| Device flyer | 1.2 MB | Download |

modules & attachments

| SF64.0501 | Tool Shuttle 32mm | x 1 | auf Anfrage |

|

|||

|

|

SF64.0525 | Dip Tool 0.08mm with squeegee | x 1 | auf Anfrage |

|

||

|

|

SF64.0526 | Dip Tool 0.15mm with squeegee | x 1 | auf Anfrage |

|

||

| SF64.0527 | Dip Tool 0.22mm with squeegee | x 1 | auf Anfrage |

|

|||

| SF64.0520 | Print Tool with squeegee | x 1 | auf Anfrage |

|