LaserPro 3000

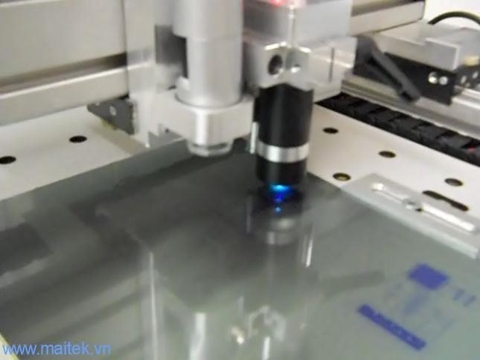

The Bungard laser unit is an add-on-item for the Bungard CCD to expose

photoresists, solder masks and Alucorex. The laser is mounted into the spindle holder instead of the high frequency spindle and is controlled by the RoutePro 3000 software.

The Bungard laser exposure unit is an answer to the demand of many operators for higher precision, faster processing speeds and reduced tool costs, as it is the case for example with isolation milling.

Chính sách bán hàng

Thông tin chi tiết

Bungard Laser Direct Imaging (LDI)

LaserPro 3000

The Bungard laser unit is an add-on-item for the Bungard CCD to expose photoresists, solder masks and Alucorex. The laser is mounted into the spindle holder instead of the high frequency spindle and is controlled by the RoutePro 3000 software. The Bungard laser exposure unit is an answer to the demand of many operators for higher precision, faster processing speeds and reduced tool costs, as it is the case for example with isolation milling.

As a result, it is possible to switch from isolation milling to wet processing without the exposure unit and photoplotter.

Please note that this inexpensive add-on gives excellent results for prototypes, but due to its technology, it is much slower than an industrial direct imager.

Converting Gerber to HPGL works best when macros and polygons are avoided when making the Gerber export from your design software.

Laser class: class 3B

Power:120 mW

Dimensions (LxWxH):47 x 47 x 110 mm

Line resolution: 50 - 1000 µm / max. 25 - 3000 µm

Requirements

- a Bungard CCD

- the Software RoutePro 3000

- a laser licenseLaserPro 3000 (scope of delivery laser license)

- a switch box to connect laser to the CCD (scope of delivery laser license)

- a laser exposure head

Operating

To use the laser functions you need to connect the laser to the CCD and activate a laser license. The laser moves similar to routing along HPGL vectors. With the travelling height the line width and with laser intensity and travelling speed the exposure intensity is defined.

We recommend to adjust the step resolution to one eight in the software RoutePro 3000.

Safety regulations

The laser exposure unit may only be used in connection with a CCD.

The laser can only be switched on, when it is correctly installed into the spindle holder of the CCD.

The laser itself has a power 120 mW and is classified as laser class 3B.

The laser is set into the CCD in a way, which makes it impossible to look directly into the laser light.

Note: the laser exposure unit may only be operated in a closed rack or hood.

Please observe the general rules for handling electronic parts, especially ESD-protection.

Before touching the laser head, perform a potential compensation.

E.g put you both hands on an ESD-suitable support before removing the laser from the package.

You need to do the same, before you reassemble the laser from the machine.

By bad conditions like, PVC flooring and shoes with plastic soles, high static charges can occur.

These could damage the laser head.

Techn. Data

Laser class: class 3B

Power: 120 mW

Dimensions (LxWxH): 47 x 47 x 110 mm

Safety:

a) Magnetic safety switch; laser turns on only if the unit is mounted facing downward into the CCD holder

b) PVC-protection cover with door switch and fi lter screens recommended

Power connection: Via Bungard CCD

Control: Via Bungard CCD/RoutePro3000

Requirements:

Bungard CCD

Software RoutePro 3000

Laser-Lizenz für RoutePro 3000

Application:: Exposure by UV-laser diode; wave length approx. 406 nm; suitable for positive- and negative photoresist, solder mask and Alucorex

Travel speed: (depending on resolution and type of photoresist:) 100mm – 10.000mm/min Average speed: 1.000 mm/min

Line resolution: typically and specified: 50 - 1000 µm, max. possible 25 - 3000 µm