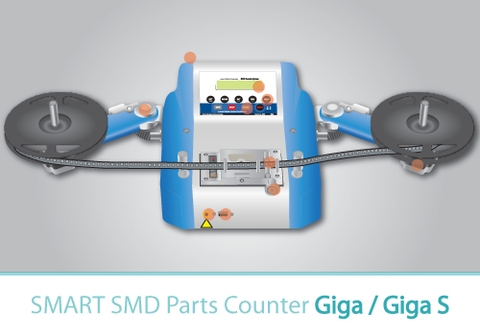

Máy đếm linh kiện điện tử Giga / Giga S

Chính sách bán hàng

Thông tin chi tiết

1. Fearture

- Double-check feature ensures accuracy

- Pocket Check(Missing Parts-Only Giga S) feature stops counting and stop or pass depending on setting when an empty pocket is encountered.

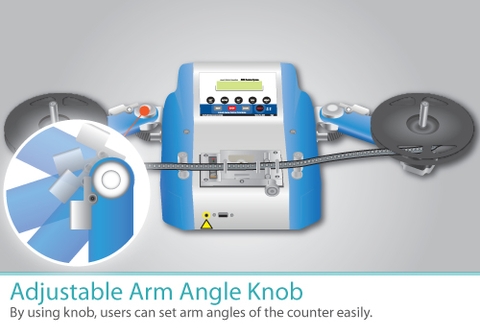

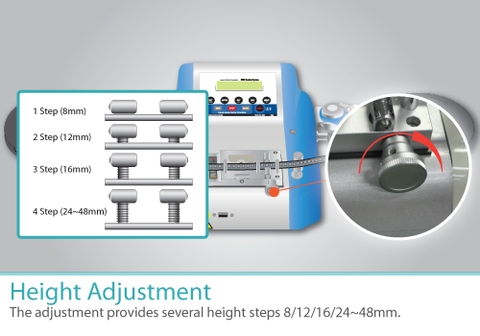

- Adjustable pocket check sensor height unlike other products adopt fixed sensor height

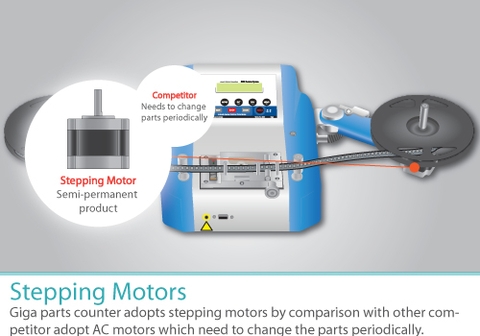

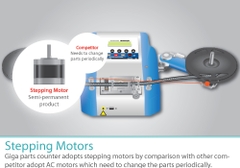

- Stepping Motor(Semi Permanent Product) instead of AC motor which needs to be replaced periodically

- Can complete a 5,000 part reel in 60 seconds(with pitch = 1)

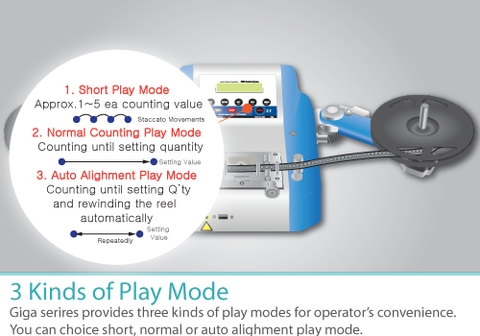

- 3 Play modes (Short, Normal, Auto-alighment)

- Count forward and backward

- Audible alarm indicates preset count has been reached

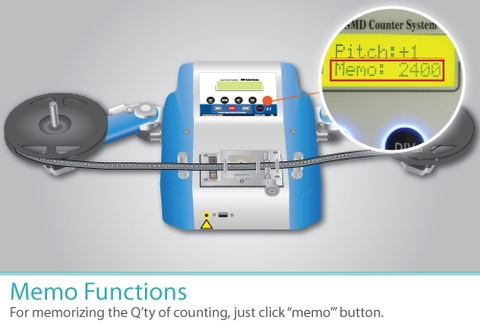

- Built in memory allows you to preset count Q'ty

- Accommodates to 440mm diameter.

- Anti-Static Connector

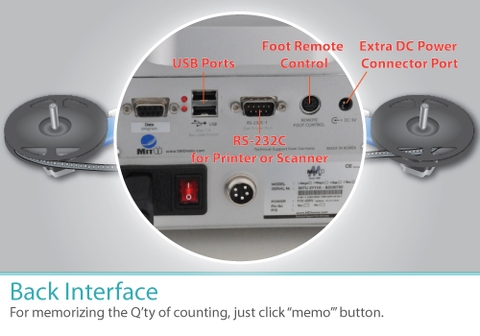

- Multi Interface (USB Ports(op), RS-232C Ports,Extra DC Adaptor Port)

- Control Beep Sound

- Free Power Volatage(110-220V)

- Auto Power Sleep Mode

- Various Accessories (Lable Printer/Barcode Printer/Barcode Scanner/Foot remote control)

2. SUMMARY

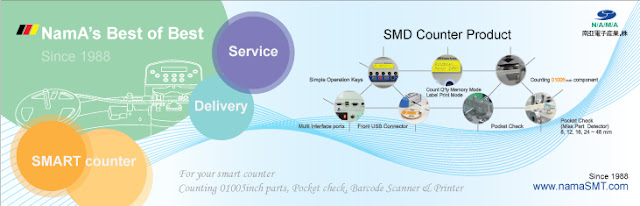

Giga which is multi functional economic SMD Counter system, is the most dedicated counter of NamA Electronic Industry Korea.

The automatic Giga SMD parts counter sets up and changes over fast. Count out an entire reel or a specific number of parts to prepare for your next job, and know you've got the right amount, thanks to the Giga's Pocket Check and double-check features.

The operators can see the SMD tape effectively at the front of the machine.

Specially, Giga is compatible for AC110-220V free voltage through a controlled manner to use any country in the world.

Exclusive "Pocket Check" Tracks Missing Components

Component reels often are missing components, yet most counters cannot detect this condition. The Giga S counter not only counts the sprocket holes but also has "Pocket Check," which checks each pocket to verify that the component is actually there. If there is a missed part, the machine stops or pass and, before continuing, lets operator know total number of missing components. A digital readout continuously updates the true part count by subtracting missing parts.

As an additional benefit, Pocket Check will stop at the end of new reels as they typically have 5-10 inches of empty pockets at the end of tape reel. This prevents the annoyance of spinning tape whiplash.

Ergonomic and Easy to Use

The design of the Giga allows the operator to keep an eye on the LCD screen and the parts as they're being counted at the same time. The machine counts forward and back (for double-checking), or parts can be swiftly spooled back to their original reel.

|

No |

Function |

Giga |

Giga S |

Remark |

| 1 | Motorized Auto Counter |

O |

O |

Adopt stepping motors |

| 2 | SMD (4mm-72mm) |

O |

O |

|

| 3 | SMD Pocheck Check (Missing Parts) |

X |

O (8,12,16,24~48mm) |

Adjustable knob control |

| 4 | Rechargeable Battery (7A) |

X |

X |

Optional |

| 5 | Interface 1. 2 x USB Ports 2. 2 x RS232C Ports 3. Foot Remote Ports 4. 1 x Extra Power Port (DC 5V) 5. USB Port at the front |

1. X 2. O 3. X 4. O 5. X |

1. O 2. O 3. X 4. O 5. O |

X : Optional Selection |

| 6 | Free Power Voltage 110-220V,50/60Hz |

O |

O |

* We reserve the right to make changes without notice.

3. Operation

- Place the full reel to be counted on the right side and an empty reel on the left. Manually lead the tape through the counting gears. Rotate the temp reel till the first component is aligned with the press wheel.

- Reset the counter's digital display. If desired, enter a preset number of parts to be counted.

- Set the pitch value as specified above.

- Press the START key to start counting. Note: the counter increases or decreases whether it is moved by the motors or manually.

- Rewind the tape back to the original reel by pressing the REWIND key. Rewinding also verifies the counting result.

3 Counting Mode

| 1 | Short Moving | When you press the start button shortly, the stepping motor moves shortly. It is useful for 1~3 parts moving. |

| 2 | Normal Moving | If you want to count the parts till preset value, press the start button for 3 seconds. After the machine count the parts until preset value, it will be stopped automatically. |

| 3 | Auto Alignment Moving (Test or Double Check) |

If you want to double-check the parts till preset value or check the machine's performance, press the start button for 6 seconds. After the machine count the parts until preset value, it will be rewind the reel till 0 value automatically. |

4.Interface

Indicator

|

1 |

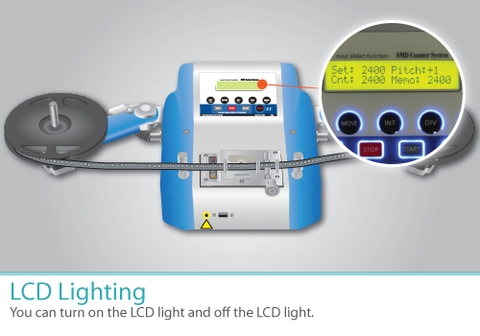

Control Panel Back Light |

On Setup |

|

2 |

3 x SMD,Dip LED |

|

|

3 |

2 x USB Port Indicator |

|

5. Accessories

6. Options

-

Rechargeable Battery

-

USB Port

-

Power Cable

-

Accessories

●Specification

|

No |

|

Feature |

Giga |

Giga S |

|

|

1 |

|

Type of parts counter |

Motorized |

Motorized |

|

|

2 |

|

Count type |

SMD |

● |

● |

|

|

Axial, Radial |

|

|

||

|

|

01005 inch (2mm pitch) chips |

|

|

||

|

3 |

|

Pocket check function for SMD chips |

|

● |

|

|

4 |

|

Mark a point on the Axial, Radial tape |

|

|

|

|

5 |

|

Memory for counting quantity |

● |

● |

|

|

6 |

|

Pin no. feature for using machine distributor |

● |

● |

|

|

7 |

|

Upgrade software with PC interface (in the future) |

▲ |

▲ |

|

|

8 |

|

Count 5,000 chips per 40~50sec. |

● |

● |

|

|

9 |

|

SMD counting direction ►:Left to Right , ◄:Right to Left) |

← |

← |

|

|

10 |

|

Bidirectional counting |

● |

● |

|

|

11 |

|

Edit company name, date, time |

● |

● |

|

|

12 |

|

Interface |

2 x RS232C Ports |

● |

● |

|

|

2 x USB Ports |

▲ |

●(+1) |

||

|

13 |

|

Keylight mode on the key pad |

● |

● |

|

|

14 |

|

Set SMD pitch (4~80mm with 20steps) |

● |

● |

|

|

15 |

|

Automatic alignment mode |

● |

● |

|

|

16 |

|

Automatic power sleep mode. (20min) |

● |

● |

|

|

17 |

|

Adjust beep sound |

● |

● |

|

|

18 |

|

Adjust LCD contrast |

● |

● |

|

|

19 |

|

Anti-static connector |

● |

● |

|

|

20 |

|

Rechargeable battery |

▲ |

▲ |

|

|

21 |

|

Bulk scale interface to connect RS232C |

▲ |

▲ |

|

|

22 |

|

Aluminum mold & Injection |

● |

● |

|

|

23 |

|

100~220V / 50~60Hz Free Power |

● |

● |

|

|

24 |

|

Extra DC adapter ( Free voltage switching adapter DC 5V / 2A) |

● |

● |

|

|

25 |

|

Standard Accessory |

1) AC power cable |

||

|

26 |

|

Option |

1. Dot Printer (label) |

● |

● |

|

|

2. Barcode Printer |

● |

● |

||

|

|

3. Barcode Scanner |

● |

● |

||

|

|

4. Foot remote ( Opt) |

● |

● |

||

|

27 |

|

Weight (kg) |

8.8 kg |

9.0 kg |

|

|

28 |

|

Weight for carton box (kg) |

11.3 kg |

11.3 kg |

|

|

29 |

|

Dimensions ( W x D x H ) |

450 x 300 x 200 |

||

|

30 |

|

Dimensions for carton box ( W x D x H ) |

450 x 360 x 280 |

||

* Product specifications and features are subject to change without notice.

●Balance Table

|

No |

Function |

I'Magic |

Giga S |

Other Company |

Remark |

|||||

|

1 |

Motorized type |

DC Stepping |

AC Motor |

|

||||||

|

2 |

Motor power |

DC 12V (Input AC free voltage) |

AC 100V or 200V |

|

||||||

|

3 |

Pocket check defact |

O |

O |

|

||||||

|

4 |

Adjust height |

8,12,16,24 ~ 48mm step knob anddelicately adjust possibility |

8mm |

|

||||||

|

5 |

SMD, Axial, Radial count |

O |

Future model |

X |

|

|||||

|

6 |

Printer type |

Barcode or Dot Printer |

Barcode |

Self Edit company name |

||||||

|

7 |

Barcode hand scanner |

O |

O |

No need power |

||||||

|

8 |

Last counting memory mode |

O |

X |

|

||||||

|

9 |

Foot remote control for counting |

O |

X |

|

||||||

|

10 |

Automatic alignment mode |

O |

X |

|

||||||

|

11 |

Interface port |

2 x RS-232C, 2 x USB |

RS-232C |

|

||||||

|

12 |

Automatic power sleep mode |

60min |

20min |

X |

|

|||||

|

13 |

Counting speed |

30~40 sec. |

40~50 sec. |

60 sec. |

|

|||||