Máy hàn chip set BGA bằng tay ZM-R6110

Bga soldering machine ZM-R6110 motherboard repair, Repair laptop machine,BGA Rework station

Main Features:

1.Embedded industrial control computer windows system. Adopt high definition human

Chính sách bán hàng

Thông tin chi tiết

Main Features:

1.Embedded industrial control computer windows system. Adopt high definition human-machine interface,PLC control,there is

password protection and modify function, can show 4 -6 temperature curves and store multiple sets of data,with instant curves analysis

function,and analyzing and correct BGA temperature at any time.

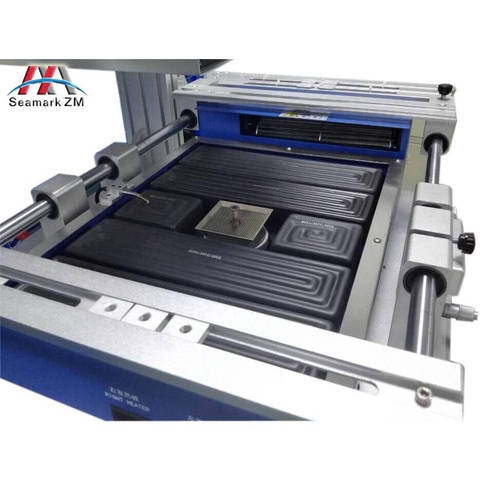

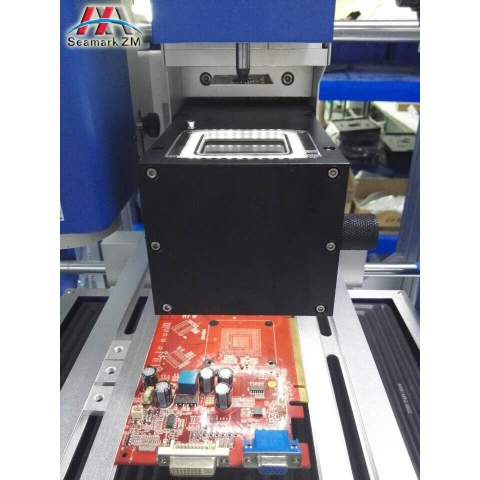

2.For guarantee the heating effect and mounting precision, control independent the top heater and mounting heater,adopted linear slide make X,Y,Z axis can do micro adjustment and rapid positioning;After mounted, no need to move the PCB board in the bottom area, it can heat directly when move the top heater, avoid the moving of bga placement when move the PCB. Ensured the mounting accuracy and welding effect. 3. top and bottom heaters are hot-air heating, the third IR heater is infrared heating, the top and bottom heaters can heat PCB from upper and bottom at the same time, three heaters control independently. Show the heat time, temperature, and curves act, on the touch screen 4. choose high accurate K type close-loop thermocouple, and PID parameters automatic adjustment system,control temperature

precisely through PLC and temperature module, keep the temperature deviation at ±2 degree.external temperature measuring interface check temperature precisely, achieve accurate analysis and collate the actual temperature curve.

5. V-groove PCB support, with rapid, convenient and accurate positioning, can fit for all kinds of PCB board.

6. Flexible and removable universal fixture the operator and the protective effects and no damage to the PCB board,suitable for all kinds of sizes of BGA repair. 7. Adopted all kinds of BGA nozzles, with 360° rotation, easy for installation and replacement, customized is available; 8. Adopt adjustable CCD color optical system, with a beam split, zoom in, zoom out and micro-adjust functions, has automatic chromatism resolution and brightness adjustment system, can adjust the clearness of the image by hand or automatic. 9. The X, Y axis and R angle with micrometer adjust; alignment accuracy is within ±0.01mm, with high definition HD monitor, avoiding human operation errors completely. 10. There are 8 segments rising temperature and 8 constant temperatures, can store millions of temperature curves, curve analyze, set and modify on the touch screen. 11. With voice control “alarm in advance” function, 5-10 seconds before finished soldering and desoldering alarm the operators with voice control to prepare the related works. Powerful cross-flow fan cool the PCB board fast by hand or automatic after desoldering and soldering, it can prevent the PCB board from deformation, ensure the welding effect. 12. With vacuum pump,Φangle 60° rotation, micrometer precise adjust mounting and nozzle, need no air source. 13. With CE certification, there is emergency stop switch and automatic cut off protective device when abnormal situation happen.

1

Total Power

4850 W

2

Top heater

1200 W

3

Bottom heater

The second heat area 1200 W, the third heat area 3900 W (plus size area to suit any kinds of PCB board)

4

Power

AC220V±10% 50/60Hz

5

Dimensions

L790×W640×H800 mm

6

Positioning

V-groove, PCB support can X,Y axis adjust at any direction, additional with universal fixture

7

Temperature control

K Sensor, Closed loop

8

Temperature accuracy

±2 degree

9

PCB size

Max 370 x 410mm Min 22 x22mm

10

Work bench fine-tuning

front and back ±15mm, right and left ±15mm

11

Camera magnification

10x-100x times

12

BGA chip

2*2-80*80mm

13

Minimum chip spacing

0.15mm

14

External Temperature Sensor

1-5 pieces available to choose, optional

15

Placement Accuracy

±0.01MM

16

Net weight

93kg