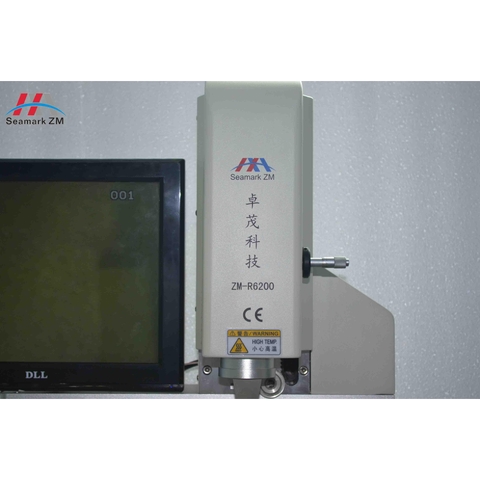

Máy hàn chip set BGA tự động ZM-R6200

Automatic BGA rework station ZM-R6200

Main Features:

1, ZM-R6200 is the highest cost-effective machine for BGA|SMD rework in Seamark ZM.

2, High automatic,easy operation for

Chính sách bán hàng

Thông tin chi tiết

Main Features:

1, ZM-R6200 is the highest cost-effective machine for BGA|SMD rework in Seamark ZM.

2, High automatic,easy operation for BGA rework,SMD rework, micro ic components rework.

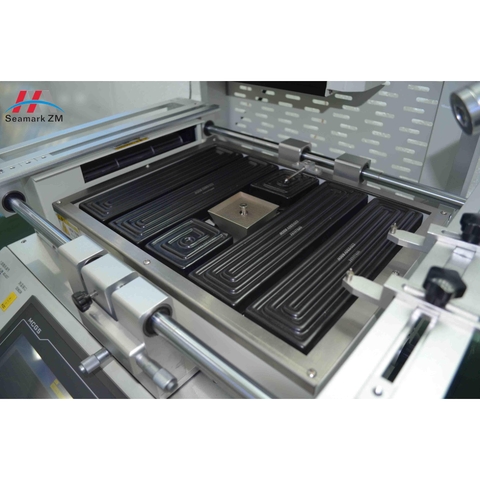

3,Good effect of constant temperature heating,longer serve life.

4, CCD camera optical alignment system helps position precisely.

5,Built-in pressure testing device protects the PCB.

6, Laser pointer, fast positioning for PCB.

7, High Definition touch screen( up to 800*600 pixel).

8, Real-time automatic monitoring for all heaters, when accident happens, self-protection function works.

|

1 |

Total power |

Max5300W |

|

2 |

Top hot air heater power |

1200W (1st heater) |

|

3 |

Bottom hot air heater power |

1200W (2nd heater) |

|

4 |

3rd IR heater |

2700W |

|

5 |

power |

AC 220V±10 50/60Hz |

|

6 |

Electrical materials |

temperature control systemAdoptedDalianUniversityof Technology |

|

7 |

Dimensions |

L640*W630*H900mm |

|

8 |

Temperature control |

K-type thermocouple (Closed Loop), intelligent temperature compensation system |

|

9 |

Positioning |

V type groove,with universal fixture |

|

9 |

P C B size |

Max 410×370mm, Min65×65mm |

|

10 |

Available BGA chip |

2×2~ 80×80mm(min 0.04*0.04 inch) |

|

11 |

External temperature sensor |

1piece |

|

12 |

Net weight |

65kg |

|

13 |

Package |

Wooden box |

|

14 |

G.W. |

120KG |

|

15 |

MachineDimension |

L75cm*W75cm*H90cm |

|

16 |

Wooden box dimension |

L78*W76*H104cm |