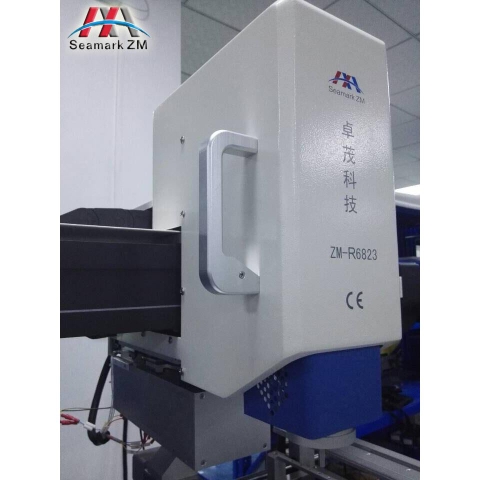

Máy hàn chip set BGA tự động ZM-R6823

ZM-R6823 automatic advanced BGA rework station with optical alignment system

3 independent control heaters

1. Integrated design of top heater with efficient ceramic heater; Air source, inclu

Chính sách bán hàng

Thông tin chi tiết

3 independent control heaters

1. Integrated design of top heater with efficient ceramic heater; Air source, including compressed air and nitrogen, is changed freely to meet repairing requests.

2. It is convenient to use bottom heater and top heater in the meantime by the system of synchronized operation and electric lift.

3. Large size IR heater, high performance heat pipes and the micro crystal plate so that preheat PCB thoroughly.

Precise optical alignment system

Adopt adjustable CCD color optical system, with a beam split, zoom in, zoom out and micro-adjust functions, has automatic chromatism resolution and brightness adjustment system, can adjust the clearness of the image,

With15”HD monitor. High automatic can avoid human error; can repair the lead-free socket 775 and double deck BGA chipset very well. It is good for lead-free repairing.

Multi-function operation system

1,.Adopt high definition human-machine interface, available for setting set up and operation to avoid error settings, the top heater device and mounting head2 in1 design, lead-screw drive, Z axis controlled by Panasonic servo control system, can control the positioning precisely.

2. With automatic identify BGA chips and mounting height; it is of automatic soldering and de-soldering function. after start, it will show 3 temperature curves on the touch screen, the precision within ±3℃.Heating temperature, time, slope, cooling and alarming, all will be shown on the touch screen.

3. the alignment system is controlled by rocker, the optical lens can be moved left and right, back and forth freely by rocker. It can observe all aspects of the BGA chip. It displays clearly. The X Y axis and R angle with micrometer adjust, precise positioning, alignment accuracy is within ±0.01MM. with”+” infrared laser light for fast positioning, after positioning, it is locked automatically.

4. It can save multiple groups profiles, and analyze, set and reverse the temperature curves at any time, You can print, save and analyze the curve through the USB port without other external devices (such as computer).

Mounting and de-mounting chips automatically.

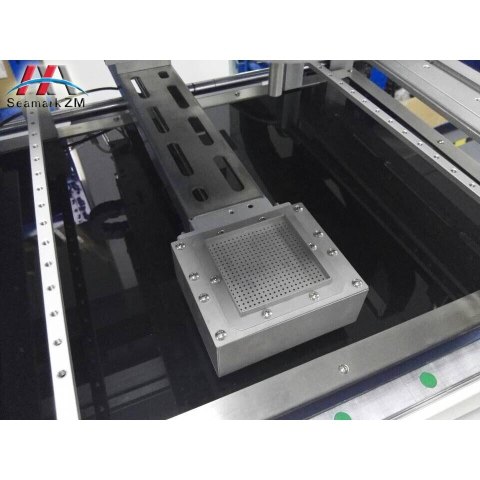

5. V-groove PCB support, with rapid, convenient and accurate positioning, can fit for all kinds of PCB board; Flexible and removable universal fixture has protective effects and no damage to the PCB board, suitable for all kinds of Sizes of BGA repair.

Superior safety functions

1. With CE certification, emergency button and abnormal incident power off automatically protect device, with protective screening, to protect the operator and the spare parts from damage. After de-soldering and soldering,

2. There is alarming. When temperature goes out of control, the circuit will automatically power off. It is of double over temperature protection function. Temperature parameter has a password to avoid from arbitrary changes,

with superior safety protection functions, can protect PCB board components and the machine from damage at any abnormal situation.

|

1 |

Power |

AC 380V 50/60Hz |

|

2 |

Total Power |

Max 5800W |

|

3 |

Heater power |

Top heater 800W, bottom 800W, IR 4000W |

|

4 |

Electrical materials |

Servo Drive system (Panasonic) +Panasonic PLC+8”Touch screen |

|

5 |

Temperature control |

K-type (Closed Loop) |

|

6 |

Positioning |

V-groove, PCB support + laser automatic positioning |

|

7 |

PCB size for |

Max 470×550mm Min 15×20 mm |

|

8 |

BGA chip for |

Max 80×80mm Min 2×2 mm |

|

9 |

Dimensions |

L890×W790×H1000mm |

|

10 |

Sensors |

4 |

|

11 |

Weight |

140kg |