Còn hàng

Máy hàn khuôn laser SKL-MW220W/400W

Tình trạng:

Còn hàng

|Thương hiệu: SKL SYSTEM

Loại: Máy Laser

Nội dung đang cập nhật...

Liên hệ

Chính sách bán hàng

Hàng chính hãng, bảo hành toàn quốc

Cung cấp đầy đủ chứng nhận CO, CQ

Gọi lại trong 10 phút từ khi nhận liên hệ

Giao hàng toàn quốc nhanh chóng

Hỗ trợ dịch vụ 24/7

Hỗ trợ mua hàng

0906182358

Thông tin chi tiết

Mould welding M/C

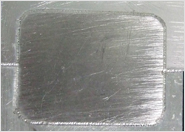

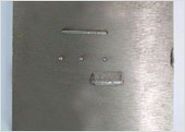

Laser mould welding machine welds a damaged part of a mold with the welding rod and hyperthermal energy generated in a short time using laser.

It makes a surface smooth through spark and grinding after welding. It generates less bubble, crack, damage and wear and precise welding is possible. Area affected by heat is small therefore precision mold is not altered. Welding depth is deep and the exterior is firm and smooth. Great dissolution doesn’t leave welding mark. The material melts in the welding area which generates no groove on the part where the mold is contacted.

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Applications |

|||||||

| Mobile phone electronic device, car, motorcycle, model manufacturing and processing | |||||||

| ▶ Suitable materials | |||||||

| S136, SKD一11, NAK80, 8407, 718, 738, H13, P20, W302, 2344 mold, carbon steel, regular alloy, stainless steel, beryllium copper, red copper, plastic mold of solid alloy material,, cast frame, forging mold, press frame, die-cast frame, etc. | |||||||

|

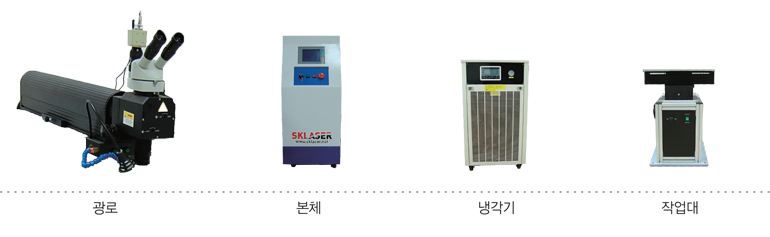

Option:

|

|

|||

| CCD camera system | Magnet jig |