Presensitized Boards

Chính sách bán hàng

Thông tin chi tiết

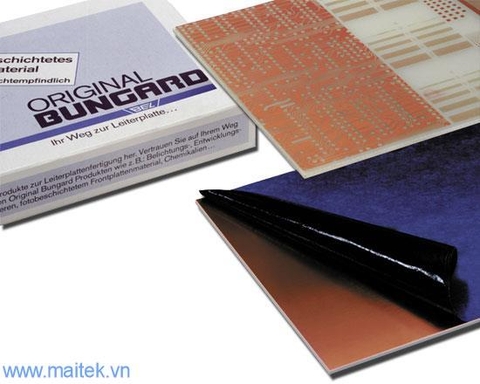

Presensitized Boards

A value concept for quality.

Our special quality can be measured in the following facts:

We use first-choice laminates approved and certified by UL, NEMA, DIN, IEC and others.

Several types of laminates such as FR2, FR3, CEM1, FR4 and PTFE are available in different thicknesses and copper clads. FR 4 e.g is available in thicknesses of 0.5, 0.8, 1.0, 1.6, 2.0 and 2.5 mm with either 18, 35 or 70 microns Copper. The max. panel size is 510 x 1150 mm. Our cutting service provides sheets down to 50 x 50 mm min. size, with an accuracy of 0.1 mm.

Photoresist

We coat the laminates with a special positive working liquid resist made after our own recipe. The resist features highest exposure sensitivity, short processing turns and large safety tolerannces. The equal and dust-free coating has a defined thickness of 5 µm. The maximum spectral response is in the range of 350 - 400 nm. The line resolution is limited only by the type of exposure unit. Typical exposure times are less than 90 secondes on our exposure unit HELLAS with fluorescent vacuum tubes. The resist allows multiple exposure.

Referring to our special developer, at 20 °C the developing time is less than 45 secondes. On the other hand, the resist is absolutely stable for more than 5 minutes in the developer. It is resistant to acid etching or galvanic chemicals and even permits alcaline etching at a ph less than 9.5.

The boards are protected against mechanical damage and unwanted exposure by a special, blue coloured adhesive foil. Due to this protective foil, no flitters appear when cutting or milling the boards.

Each board is subjected to chemical and physical controls and tests before and after coating.

A shelf live of more than 1 year under normal storage conditions is guaranteed. Even 10 year old boards still work.

Presensitizing Service

We can coat boards that you supply with photoresist. The max. board size is 530 x 1160 mm, the min. board thickness is 0.3 mm. Our pre-sensitizing service includes cleaning, double sided coating in dip technology, pre-aging, optical control and protection foil. Attention: dip rim 10mm on top and drip rim of 10 mm at the bottom will reduce usable size by 20 mm on the short side (530 mm will go down to 510 mm). The rim is on request removed without charge.

|

New ! FR4 thin laminate in 0.125mm und 0.2 mm thickness For semiflex application and multilayer! The Bungard semiflex base material combines the advantages of the simple processing of the Bungard standard base material with flexibility for special applications. Please note that we sell boards of 100x160 only in units of 35 and 210x300 only in units of8 boards. |

|

New ! Bungard Cotherm:

For many applications customers demand a better thermal dissipation (LED). One possible solution for heat problems are so called metal core boards, which consists of a 35 µm copper layer, a 100 µm isolation layer (FR4) and a 1000-2000 µm Aluminium layer.

Bungard company offers this PCB type with brand name Cotherm. Cotherm is available with or without photosensitive resist and in these formats:

Metal Core Boards Cotherm 1000/100/35 µm; Format 530 x 1180mm (1,0 mm; 1 x 35 CU);

Metal Core Boards Cotherm 1500/100/35 µm; Format 530 x 1180mm (1,5 mm; 1 x 35 CU);

Dripping and clamping rim reduces the format to 510x1150 mm for Cotherm with photocoat.

Standard cuttings FR4

| Format (mm) | |||

| 1.5 mm 35 μm Cu |

1.5 mm 70 μm Cu |

||

| 210 x 300 | 210 x 300 | ||

| 200 x 250 | 200 x 250 | ||

| 150 x 250 | 150 x 250 | ||

| 160 x 233.4 | 160 x 233.4 | ||

| 150 x 200 | 150 x 200 | ||

| 125 x 175 | 125 x 175 | ||

| 100 x 160 | 100 x 160 | ||

| 75 x 100 | 75 x 100 |

Panels FR4

| Format (mm) | |||||

| 0.5 – 1.5 mm 18 μm Cu |

0.5 - 2.5 mm 35 μm Cu |

0.5 - 2.5 mm 70 μm Cu |

1.5 mm 105 μm Cu |

1.5 mm FR4 blue/black 35μm |

|

| 510 x 1150 x 0.5 | 510 x 1150 x 0.5 | 510 x 1150 x 0.5 | 510 x 1150 x 1.5 | 510 x 1150 x 1.5 | |

| 510 x 570 x 0.5 | 510 x 570 x 0.5 | 510 x 570 x 0.5 | |||

| 510 x 1150 x 0.8 | 510 x 1150 x 0.8 | 510 x 1150 x 0.8 | |||

| 510 x 570 x 0.8 | 510 x 570 x 0.8 | 510 x 570 x 0.8 | |||

| 510 x 1150 x 1.0 | 510 x 1150 x 1.0 | 510 x 1150 x 1.0 | |||

| 510 x 570 x 1.0 | 510 x 570 x 1.0 | 510 x 570 x 1.0 | |||

| 510 x 1150 x 1.5 | 510 x 1150 x 1.5 | 510 x 1150 x 1.5 | |||

| 510 x 570 x 1.5 | 510 x 570 x 1.5 | 510 x 570 x 1.5 | |||

| 510 x 1150 x 2.0 | 510 x 1150 x 2.0 | ||||

| 510 x 570 x 2.0 | 510 x 570 x 2.0 | ||||

| 510 x 1150 x 2.5 | 510 x 1150 x 2.5 | ||||

| 510 x 570 x 2.5 | 510 x 570 x 2.5 | ||||

Panels FR2

Format 480 x 1000 x 1.5 mm35 µm Cu single or double sided

Panels FR3

Format 510 x 1150 x 1.5 mm35 µm Cu double sided

Panels CEM1

Format 510 x 1150 x 1.5 mm35 µm Cu single sided

Panels CEM9 Blue Stock sale

Format 440 x 1150 x 1.5 mm 35 µm Cu double sided

Cutting Service

We cut down all boards to non-standard sizes on request. The maximum board size is 510 x 1150 mm, the minimum size is 50 x 50 mm. Rests will be included.

Boards >= 2 mm will be cut by saw. Saw cutting loss will be 3 mm per piece.

|

|

|

|